HOME > Mold Parts

- Our Products

Processing By Order (per materials)

Surface Process Effects - Mold Parts

・Injection Mold Parts

・Press Metal Frame Parts

・Die-Casting Metal Mold Parts

・Tablet Press

・Semi-Conductor Molding

・Diamond Parts - Automated Parts/Jig Parts/Devises

・Automated Parts

・Jig Parts

・Process Parts

・Assembling Parts

・Prototype Devises

・Mass Production Devises - Mold and Die Design and Manufacturing

- EMS (Electric Manufacturing Service)

- Our Facilities

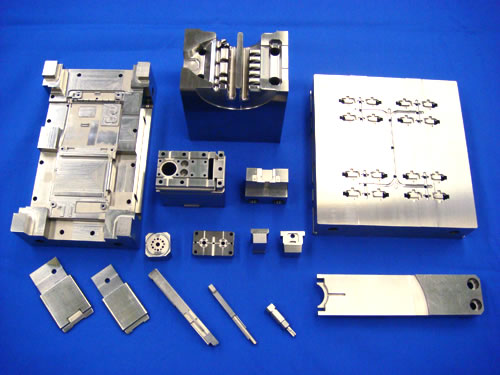

Injection Mold Parts

We handle in wide range; from ultra-fine precision parts to 3D mass-size parts, with those cutting, grinding, electric discharge, wire cutting, and polishing.

Our Deliverance Results

light electrical appliance industry, semi-conductor industry, auto industry, medical industry

Procedures

grinding, electric discharging, wiring, cutting, 3Ding, and polishing.

Precision Guarantee

Although it varies depending on shape/materials/process, we basically guarantee a precision of 0.5-1μ (grinding), 2μ (EDM/WEDM method) and 2μ (machining).

Press Metal Frame Parts

We handle various materials such as steel, ultra-hard, and ceramic materials. We also handle precision process such as mirror-surface profiling process, extra-thin wiring process.

Our Deliverance Results

light electrical appliance industry, semi-conductor industry, auto industry, medical industry

Procedures

grinding, electric discharging, wiring, cutting, 3Ding, and polishing.

Precision Guarantee

Although it varies depending on shape/materials/process, we basically guarantee a precision of 0.5-1μ (grinding), 2μ (EDM/WEDM method) and 2μ (machining).

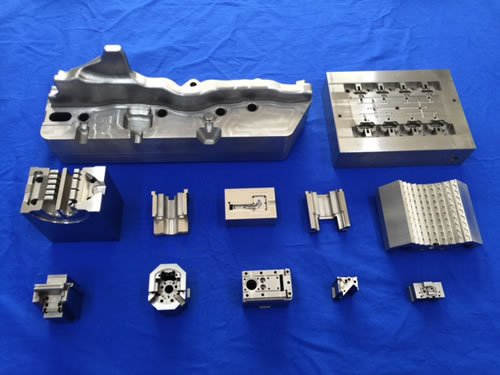

Die-Casting Metal Mold Parts

We handle in wide range; from ultra-fine precision parts to 3D mass-size parts.

Our Deliverance Results

light electrical appliance industry, auto industry, construction Industry

Procedures

electric discharging, wiring, cutting, 3Ding.

Precision Guarantee

Although it varies depending on shape/materials/process, we basically guarantee a precision of 0.5-1μ (grinding), 2μ (EDM/WEDM method) and 2μ (machining).

Tablet Press

Materials such as hardened steel and carbide can also be used. We can propose coating finish as well as mould release prevention.

Our Deliverance Results

Pharmaceutical Industry, Confectionary Industry, Fiber Industry

Procedures

grinding, electric discharging, wiring, cutting, 3Ding.

Precision Guarantee

Although it varies depending on shape/materials/process, we basically guarantee a precision of 0.5-1μ (grinding), 2μ (EDM/WEDM method) and 2μ (machining).

Semi-Conductor Molding

For pot plunging, gate parts, plating, we propose sclerotic fiber molding.

Our Deliverance Results

Electric Appliances Parts Industry

Procedures

grinding, electric discharging, wiring, cutting, 3Ding, and polishing.

Precision Guarantee

Although it varies depending on shape/materials/process, we basically guarantee a precision of 0.5-1μ (grinding), 2μ (EDM/WEDM method) and 2μ (machining).

Diamond Parts

Using PCD (Polycrystalline Diamond) gives high density and long-lasting features.We have experiences in adapting punch-die for press mold, various collet nozzles and various parts.Maintenance-free quality gives you high productivity.

Characteristics/

Advantages

- ①Super High Quality Anti-Abrasion:

- The degree of Vickers hardness (Hv8,000-10,000) is very high, so the anti-abrasion quality is superb (4-6 times harder than cemented carbide).

- ②High Toughness:

- High shock-resistance protects against chipping.

- ③Low-Level Distortio:

- May be used for a long time with limited deterioration.

- ④Long Life:

- If used for metal punching, die-casting etc., it may be used for a long time with minimal maintenance required. We have achieved an increased life expectancy of 70-100 times longer.

We can provide various solutions to our customers’ needs.

We can do: 1. ultra-high brazing, 2. ceramic attachment, and 3. CBN (cubic boron nitrate), so we are waiting for your order.

Processing By Order (per materials)

| Resin | super engineering plastic, plastic for multi-purpose, heat-hardening plastic, engineering plastic, |

|---|---|

| Aluminum | pure aluminum, free-cutting aluminum, high-temperature hard aluminum, corrosion resistant aluminum |

| Copper Alloy | pure bronze, brass, phosphor bronze, high tensile brass, bronze casting |

| Stainless Steel SUS | SUS301/303/304/316/420/430/440/630/631 |

| Nickel Alloy | hastelloy, permalloy, kovar, inconel, monel |

| Steel Materials | normal steel -SS500・S50C・SCM・SUM・SPSS・SPHC special steel -SK・SKS・SKD・SKH・DC・NAK・PX・STAVAX・RIGOR・PD・ELMAX・HPM・ASP・HAP・NAS・YAG |

| Carbide | ultra fine particles, binder-less alloy, nonmagnetic carbide |

| Ceramic | aluminum nitride, silicone nitride, alumina, zirconia |

| Others | titanium alloy, tungsten, molybdenum, magnet, magnesium alloy |

| Composite Material(brazing, thermal insert, chilled insert, crimping, welding,) CBN, PCB |

Processing By Order (per materials)

| Surface Process Effects | anti-rust, anti-abrasion, lubricating, surface lubricating, anti-magnetism, reflection prevention, heat tolerance, anti-adhesiveness, tolerability, anti-microbe, electric non-conductance |

|---|

| Metal Plating | metal plating - zinc, electro-less NI, hard chrome, chrome, alumite chemical process - black oxide finish, parkerizing, chrome coating |

|---|

| PVD physical vapor deposition | TIN・TIALN・TICN・DLC・CrN |

|---|---|

| CVD chemical vapor deposition | TIC・TICN |

| Softnitriding/TD Process | gas softnitriding, ion-nitriding, various softnitriding, TD process |

|---|

| Surface Reforming | WPC, blasting, wrapping, buffing, other various process |

|---|

| Others | metal spraying, evaporation, painting, electrolytic polishing |

|---|

Your Order for Parts Processing

Kindly attach an illustration/data (2D/3D) for our quotation. After discussion regarding any further details, we will process/check/deliver your order.

We can give a fast quotation if requested. Normally, an inquiry which is made between 9:00 am and 12:00 noon will be processed by close of business the same day. An inquiry made from 1:00 pm will normally be processed either by close of business the same day or by the morning of the following business day.